Beyond the Mixer: Why Strategic Combination Drives Impact

Mixing, at its core, is the act of combining distinct elements to create a new, unified whole. While often associated with audio engineering, the principles of mixing extend far beyond the recording studio, influencing fields as diverse as chemical engineering, culinary arts, and even social policy. Understanding why mixing matters and who should care is the first step in appreciating its profound impact on achieving desired outcomes. This article delves into the multifaceted nature of mixing, exploring its fundamental importance, historical context, analytical frameworks, inherent challenges, and practical applications.

The Indispensable Role of Mixing Across Disciplines

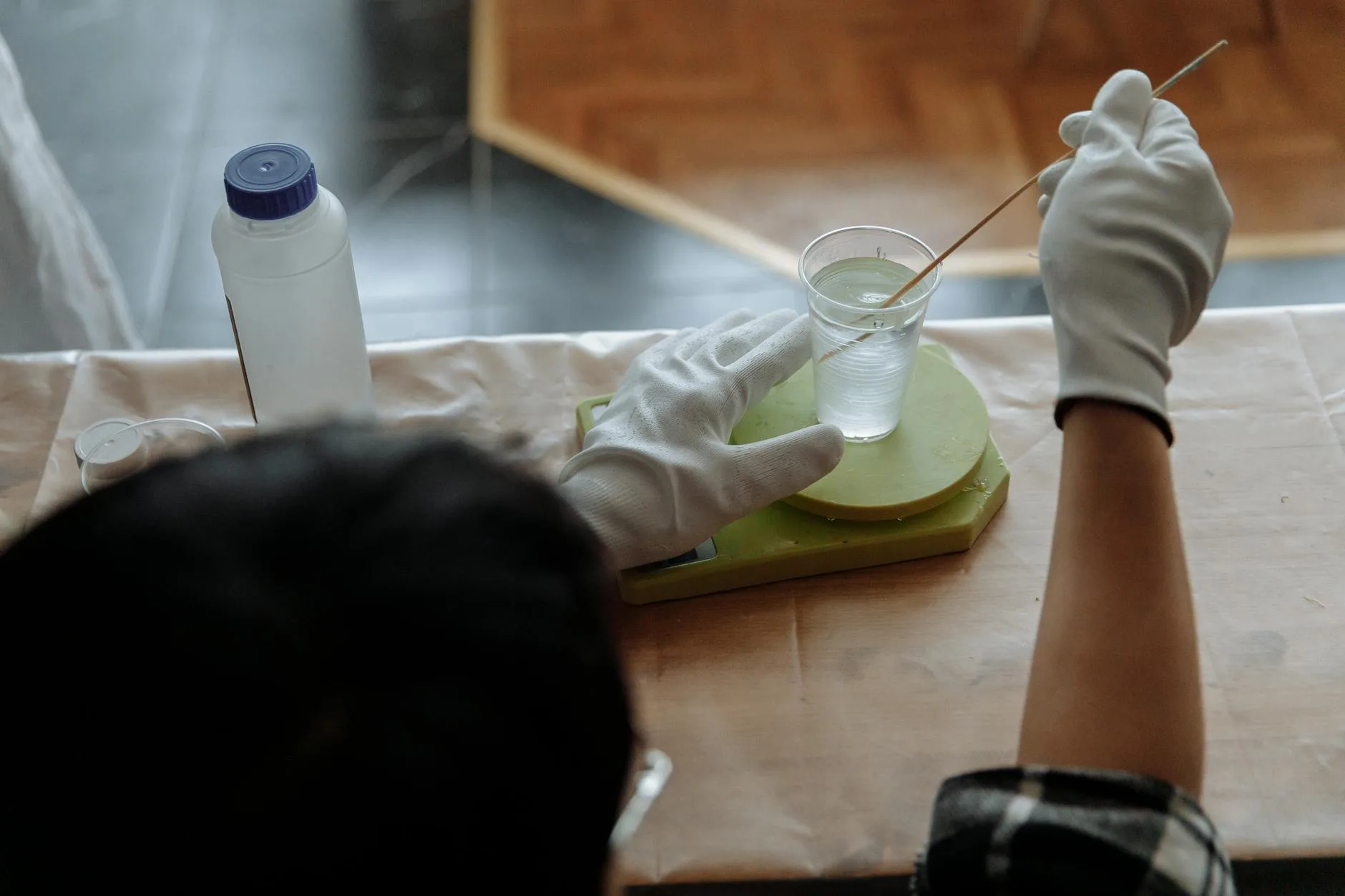

Mixing is fundamental to countless processes. In the physical sciences, mixing is essential for chemical reactions, material synthesis, and the creation of homogeneous mixtures with specific properties. A chemist meticulously mixes reagents to synthesize a new compound, understanding that the order, rate, and intensity of mixing can dictate the reaction’s efficiency and purity. Similarly, in materials science, mixing powders or liquids at precise ratios creates alloys or composite materials with tailored strength, conductivity, or flexibility.

Culinary arts provide a readily accessible example. A chef combines ingredients not just for flavor, but for texture and structural integrity. A perfectly mixed cake batter, for instance, relies on the even distribution of flour, sugar, fat, and leavening agents. Overmixing or undermixing can lead to a dense, tough cake or one that crumbles easily. The successful outcome is directly dependent on the skillful execution of the mixing process.

Beyond these tangible examples, mixing is also critical in less obvious domains. In public health, mixing vaccines with diluents is a standard procedure, requiring precise ratios to ensure efficacy and safety. In environmental engineering, mixing is used to disperse pollutants evenly for treatment or to oxygenate water bodies. Even in economics, the “mixing” of different investment strategies aims to diversify risk and optimize returns.

Who should care about mixing? Anyone involved in processes that require the integration of multiple components to achieve a desired result should care. This includes:

- Scientists and researchers

- Engineers (chemical, materials, mechanical)

- Chefs and food technologists

- Pharmaceutical professionals

- Environmental managers

- Investors and financial analysts

- Anyone aiming to create something new or improve an existing process by combining elements.

A Historical Perspective on Combining Elements

The concept of mixing is as old as civilization itself. Early humans mixed pigments to create paints for cave art and combined grains with water to bake bread. The development of agriculture involved mixing seeds with soil and later, mixing different crop varieties to enhance yields or resilience.

The scientific understanding of mixing began to crystallize with the advent of chemistry. Early alchemists, though often shrouded in mysticism, performed rudimentary mixing experiments. The formalization of chemistry in the 18th and 19th centuries brought a more systematic approach. Antoine Lavoisier’s work on stoichiometry, for instance, highlighted the importance of precise ratios in chemical reactions, which inherently involves mixing.

In the 20th century, advancements in fluid dynamics and mass transfer provided deeper insights into the physical mechanisms of mixing. The development of various mixing devices, from simple stirrers to complex industrial impellers and static mixers, reflects a growing understanding of how to control the process for specific applications. The digital revolution has further enhanced mixing, enabling sophisticated modeling and simulation of mixing processes, allowing for optimization before physical experimentation.

Dissecting the Dynamics: Perspectives on Mixing Processes

The analysis of mixing can be approached from several perspectives, each offering unique insights into how and why it works.

Fluid Dynamics and Mass Transfer

From a fluid dynamics standpoint, mixing is about creating turbulence and flow patterns that bring disparate particles or molecules into close proximity. The effectiveness of mixing depends on factors like viscosity, density, flow rate, and the geometry of the mixing vessel and equipment. According to principles of fluid mechanics, higher Reynolds numbers generally indicate more turbulent flow, which promotes faster and more uniform mixing.

Mass transfer theory examines how substances move from one phase to another or within a single phase. In mixing, this involves the diffusion of molecules and the bulk movement of fluids. The rate of mass transfer is often the limiting factor in achieving complete mixing. For instance, when mixing two immiscible liquids, the interface area and the diffusion rate across it are critical. The report “Principles of Mass Transfer” by Cussler (1984) details these concepts extensively.

Thermodynamics and Mixing Entropy

Thermodynamics explains mixing in terms of energy changes and entropy. When two substances mix, there is an associated enthalpy change (heat of mixing) which can be exothermic (releasing heat) or endothermic (absorbing heat). The spontaneity of mixing is often driven by an increase in entropy – the tendency towards disorder. According to Gibbs free energy principles, mixing is favored if the change in Gibbs free energy (ΔG = ΔH – TΔS) is negative. A positive entropy change (ΔS) contributes to a more negative ΔG, making mixing more favorable.

Process Engineering and Scale-Up

In process engineering, the focus is on designing and optimizing mixing operations for industrial applications. This involves selecting appropriate mixing equipment (e.g., agitators, static mixers, blenders), determining optimal operating parameters (speed, time, temperature), and ensuring that the mixing process can be reliably scaled up from laboratory to pilot plant to full production. Challenges in scale-up often arise because mixing dynamics do not always scale linearly. A phenomenon observed at a small scale may behave differently in a large vessel due to changes in surface-area-to-volume ratios and flow patterns. The AIChE (American Institute of Chemical Engineers) publishes extensive resources on industrial mixing and scale-up challenges.

Interfacial Science and Surface Phenomena

For mixtures involving different phases (e.g., liquid-liquid, solid-liquid), interfacial science is crucial. The properties of the interface between phases, such as surface tension, significantly influence how easily and effectively components can be mixed. Surfactants, for example, are often added to reduce surface tension and promote the formation of stable emulsions, which are intimate mixtures of immiscible liquids.

Navigating the Tradeoffs and Limitations of Mixing

Despite its power, mixing is not without its limitations and inherent tradeoffs.

- Energy Consumption:Effective mixing often requires significant energy input, especially for viscous materials or large volumes. This can lead to high operational costs and environmental considerations related to energy generation.

- Shear Forces and Material Degradation:High shear rates, necessary for breaking down aggregates or achieving fine dispersions, can sometimes damage delicate materials. For example, in food processing, excessive mixing can degrade proteins or alter the texture of sensitive ingredients.

- Incomplete Mixing and Segregation:Achieving perfect homogeneity can be extremely difficult, particularly with materials of vastly different densities, viscosities, or particle sizes. Segregation, where components separate over time or due to external forces, is a common problem.

- Contamination:In sterile environments or when dealing with highly pure substances, the mixing process itself can introduce contaminants from equipment or the surrounding atmosphere.

- Time Constraints:Some mixing processes can be time-consuming, impacting production throughput and efficiency.

- Difficulty in Viscous Fluids:Mixing highly viscous fluids is notoriously challenging. It requires specialized equipment and can be inefficient, often leading to poor homogeneity.

The tradeoff often lies between the degree of mixing achieved and the resources (energy, time, equipment) expended. There is also a balance between achieving homogeneity and avoiding unwanted side effects like material degradation or contamination.

Practical Guidance for Effective Mixing

Successful mixing requires careful planning and execution. Here’s a practical guide:

1. Define Your Goal:

Clearly articulate what constitutes a “successful mix” for your specific application. Is it uniform particle distribution, complete dissolution, a specific reaction rate, or a desired texture?

2. Understand Your Materials:

Characterize the physical and chemical properties of each component: viscosity, density, particle size, solubility, reactivity, shear sensitivity, etc.

3. Select Appropriate Equipment:

Choose mixing equipment suited to your materials and desired outcome. Options range from simple spatulas and whisking to industrial-grade impellers, high-shear mixers, and static mixers.

4. Optimize Operating Parameters:

Experiment with and adjust parameters such as mixing speed, duration, temperature, and the geometry of the mixing vessel. For instance, in audio mixing, adjusting the ‘pan’ knob to position a sound in the stereo field is a form of mixing.

5. Consider Order of Addition:

The sequence in which components are added can dramatically affect the final mixture, especially in chemical reactions or when forming emulsions.

6. Monitor and Evaluate:

Develop methods to assess the quality of your mixture. This could involve visual inspection, microscopy, chemical analysis, rheological measurements, or, in audio, listening critically.

7. Be Mindful of Scale-Up:

If transitioning from lab to production, anticipate that mixing dynamics may change. Consult engineering principles or conduct pilot studies to ensure successful scale-up.

8. Safety First:

Always adhere to safety protocols, especially when working with hazardous chemicals or high-energy mixing processes.

Key Takeaways for Mastering the Mix

- Universality:Mixing is a fundamental process underpinning success in science, engineering, culinary arts, and beyond.

- Multidisciplinary Approach:Understanding mixing requires insights from fluid dynamics, mass transfer, thermodynamics, and interfacial science.

- Tradeoff Management:Achieving desired homogeneity often involves balancing energy, time, cost, and potential for material degradation.

- Context is Crucial:The optimal mixing strategy is highly dependent on the specific materials and the intended application.

- Systematic Approach:Effective mixing is achieved through careful definition of goals, understanding of materials, appropriate equipment selection, and parameter optimization.

References

- Cussler, E. L. (1984). Principles of Mass Transfer. Cambridge University Press. Link

- McCabe, W. L., Smith, J. C., & Harriott, P. (2001). Unit Operations of Chemical Engineering. McGraw-Hill. (Covers extensive material on mixing equipment and principles).

- American Institute of Chemical Engineers (AIChE). (Ongoing). Publications and technical divisions dedicated to process intensification and mixing technologies. Link