Beyond the Blueprint: How Computational Tools Reshape Industries and Empower Creators

In an era defined by rapid technological advancement, the ability to design, simulate, and manufacture complex products efficiently and accurately is paramount. Computer-aided technologies, encompassing Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and Computer-Aided Engineering (CAE), have moved from niche professional tools to indispensable components of almost every modern industry. These integrated systems allow engineers, designers, and manufacturers to conceptualize, refine, and produce goods with unprecedented speed, precision, and cost-effectiveness. Understanding the scope and impact of these tools is crucial for anyone involved in product development, innovation, or industrial competitiveness.

The significance of computer-aided technologies lies in their ability to bridge the gap between abstract ideas and tangible realities. Traditionally, the design and engineering process involved manual drafting, physical prototyping, and iterative, often time-consuming, testing. This manual approach was inherently limited by human capacity for detail, the cost of physical prototypes, and the sheer labor involved. Computer-aided systems revolutionize this by providing digital environments for creation and analysis, enabling faster iteration, complex geometric modeling, and sophisticated simulations that would be impossible or prohibitively expensive otherwise.

Who should care about computer-aided technologies? The answer is broad:

- Engineers and Designers: These are the primary users, leveraging CAD for 2D and 3D modeling, and CAE for structural, thermal, and fluid dynamics analysis.

- Manufacturers: CAM software translates designs into machine instructions for CNC (Computer Numerical Control) machines, optimizing production processes.

- Product Developers and Innovators: The ability to quickly prototype and test digital models accelerates the innovation cycle and reduces time to market.

- Students and Educators: These tools are foundational for modern engineering and design education, preparing the next generation of professionals.

- Business Leaders and Decision-Makers: Understanding the strategic advantage offered by these technologies informs investment and R&D strategies.

- Consumers: Ultimately, the quality, functionality, and affordability of the products we use daily are influenced by the efficient design and manufacturing processes enabled by computer-aided tools.

Historical Roots: From Drafting Boards to Digital Workstations

The genesis of computer-aided design can be traced back to the early days of computing. While rudimentary graphical interfaces emerged in the 1950s and 1960s, the practical application of CAD began to take shape in the 1960s with systems like Sketchpad, developed by Ivan Sutherland at MIT. This groundbreaking work demonstrated the potential of interactive computer graphics for design. Early commercial CAD systems, appearing in the 1970s, were expensive and primarily used by large corporations in the automotive and aerospace industries, focusing on 2D drafting.

The 1980s saw the advent of 3D CAD, significantly enhancing the capabilities for modeling complex shapes and assemblies. This period also marked the rise of CAM software, integrating design with manufacturing processes. The advent of personal computers and more affordable workstations in the 1990s democratized access to these powerful tools, leading to their widespread adoption across a greater range of industries.

The evolution continued with the development of CAE. Initially separate, CAE tools evolved to become tightly integrated with CAD, allowing designers to perform analyses like stress, thermal, and flow simulations directly within the design environment. This integration, often referred to as Product Lifecycle Management (PLM) systems, aims to manage a product’s entire lifecycle, from conception and design to manufacturing, service, and disposal, all within a digital framework.

The Pillars of Computer-Aided Technology: CAD, CAM, and CAE

To fully grasp the impact of computer-aided technologies, it’s essential to understand the distinct yet interconnected roles of CAD, CAM, and CAE.

Computer-Aided Design (CAD): The Digital Canvas

CAD software is the foundational element, providing the digital environment for creating, modifying, analyzing, and optimizing designs. It replaces traditional manual drafting with an interactive, digital process. Early CAD systems were primarily 2D, focusing on creating precise technical drawings like blueprints. The transition to 3D modeling has been transformative, allowing for:

- Parametric Modeling: Designs are driven by parameters (dimensions, constraints) rather than fixed geometry. Changing a parameter automatically updates the entire model, facilitating rapid design iterations and variations.

- Assembly Design: Complex products consisting of multiple parts can be modeled and visualized as complete assemblies, enabling interference checks and kinematic studies.

- Surface and Solid Modeling: Advanced techniques allow for the creation of highly complex organic shapes (surface modeling) and geometrically defined volumes (solid modeling), catering to diverse design requirements.

- Documentation and Visualization: CAD generates detailed drawings, bills of materials (BOMs), and photorealistic renderings for communication and marketing.

According to industry analysis firms like CIMdata, the global CAD market continues to grow, driven by demand for advanced features and wider adoption in emerging industries.

Computer-Aided Manufacturing (CAM): Bridging Design to Production

CAM software takes the digital design created in CAD and translates it into instructions that control automated manufacturing machinery, such as CNC milling machines, lathes, and 3D printers. It optimizes machining processes by:

- Toolpath Generation: CAM software calculates the most efficient and effective paths for cutting tools or additive processes to create the desired part from raw material.

- Simulation and Verification: It simulates the manufacturing process to detect potential collisions between the tool, workpiece, and machine, ensuring error-free operation.

- Material Optimization: CAM can help minimize material waste by optimizing cutting strategies and nesting parts on stock material.

- Process Planning: It assists in defining the sequence of operations, tool selection, and cutting parameters for efficient production.

The integration of CAD and CAM is crucial for achieving efficient “design-to-manufacture” workflows. The report “The State of Manufacturing Technology” consistently highlights the importance of integrated CAD/CAM solutions for productivity gains.

Computer-Aided Engineering (CAE): The Virtual Laboratory

CAE encompasses a suite of simulation and analysis tools that allow engineers to predict how a product will perform under various conditions without building physical prototypes. This is a critical step in the design process, enabling the optimization of performance, reliability, and safety early on.

- Finite Element Analysis (FEA): Used to simulate structural integrity, stress distribution, vibration, and thermal behavior. For example, a car manufacturer uses FEA to ensure a chassis can withstand crash forces.

- Computational Fluid Dynamics (CFD): Used to analyze fluid flow and heat transfer. This is vital for designing aircraft wings, optimizing engine performance, or simulating airflow in HVAC systems.

- Multibody Dynamics (MBD): Used to simulate the motion and forces of connected parts in mechanical systems, such as robotic arms or vehicle suspension systems.

- Electromagnetic Simulation: Used to analyze electromagnetic fields, crucial for designing antennas, motors, and electronic components.

According to academic research published in journals like the “Journal of Simulation Modelling Practice and Theory,” CAE simulations can reduce the need for physical testing by up to 80%, leading to substantial cost and time savings.

Multifaceted Impact: Transforming Industries and Driving Innovation

The pervasive adoption of computer-aided technologies has reshaped numerous sectors, driving innovation and enhancing competitiveness.

Aerospace and Automotive: Precision and Performance

In these high-stakes industries, where safety, efficiency, and performance are paramount, CAD/CAM/CAE are non-negotiable. Aerospace companies use these tools to design lightweight yet robust aircraft structures, optimize aerodynamics, and simulate complex engine systems. Similarly, automotive manufacturers rely on them for designing vehicle bodies, simulating crashworthiness, optimizing fuel efficiency through aerodynamic design, and developing complex powertrain and chassis systems.

A white paper by an aerospace industry consortium noted that the adoption of advanced CAD and CAE techniques was instrumental in reducing the development cycle for new aircraft models by an average of 15-20%.

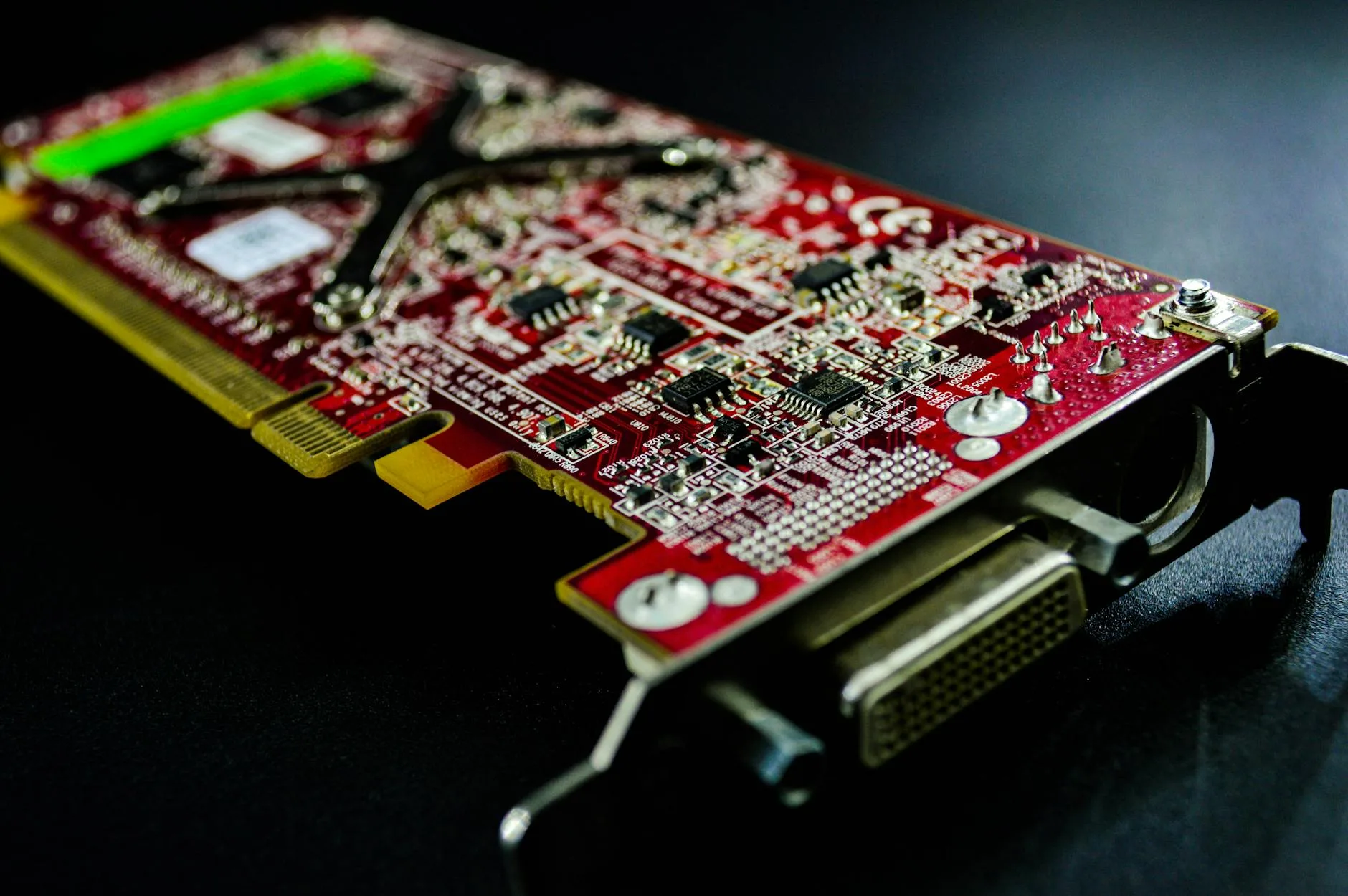

Consumer Electronics and Product Design: Aesthetics and Functionality

For consumer electronics, the ability to quickly iterate on product design, test ergonomics, and ensure aesthetic appeal is vital. CAD allows for the creation of intricate casing designs, while CAE can simulate the thermal performance of devices like smartphones and laptops. CAM ensures that these complex designs can be manufactured efficiently using methods like precision injection molding or additive manufacturing.

Architecture, Engineering, and Construction (AEC): Integrated Project Delivery

In AEC, Building Information Modeling (BIM), a sophisticated form of CAD, is revolutionizing how buildings are designed and managed. BIM creates intelligent 3D models that contain rich data about every aspect of a building, facilitating collaboration among architects, engineers, and contractors, improving cost estimation, and streamlining construction processes.

The U.S. General Services Administration (GSA) has mandated the use of BIM for federal building projects, citing its ability to improve project outcomes and reduce lifecycle costs. This highlights the growing importance of integrated digital workflows in construction.

Medical Devices: Lifesaving Precision

The development of intricate medical devices, from prosthetics to surgical instruments and implants, relies heavily on CAD for precise modeling and CAM for manufacturing. CAE plays a critical role in simulating the biomechanical interaction of implants with the human body, ensuring their safety and efficacy. For example, designing custom prosthetics often involves scanning a patient’s limb and using CAD to create a perfectly fitted, functional, and comfortable replacement.

Navigating the Tradeoffs and Limitations

Despite their immense benefits, computer-aided technologies are not without their challenges and limitations.

Cost and Complexity of Implementation

High-end CAD/CAM/CAE software suites can be expensive, both in terms of licensing fees and the powerful hardware required to run them. Implementing these systems also requires significant investment in training and ongoing support, posing a barrier for smaller businesses or organizations with limited IT resources.

Learning Curve and Skill Gaps

Mastering these sophisticated tools requires specialized knowledge and skills. There is a persistent need for trained professionals who can effectively utilize CAD, CAM, and CAE software. Educational institutions and industry training programs are working to bridge this gap, but shortages can still occur, impacting productivity.

Data Management and Interoperability

Managing the vast amounts of data generated by computer-aided design and engineering can be challenging. Ensuring smooth data exchange between different software packages and throughout the product lifecycle (interoperability) can also be problematic, leading to potential data loss or errors.

Over-reliance and Simulation Limitations

While CAE simulations are powerful, they are only as accurate as the models and data they are based on. Over-reliance on simulations without adequate validation through physical testing can lead to unforeseen issues. The accuracy of simulations depends on the fidelity of the input parameters, meshing quality, and the underlying algorithms. There are still phenomena that are difficult to model with complete accuracy.

A study published in the “International Journal of Manufacturing Technology and Management” highlighted cases where discrepancies between CAE predictions and real-world performance necessitated costly redesigns, underscoring the need for a balanced approach.

Practical Advice and Considerations for Adoption

For organizations considering or expanding their use of computer-aided technologies, several practical steps and considerations are essential:

Define Clear Objectives

Before investing, clearly identify what problems the technology is expected to solve. Are you aiming to reduce prototyping costs, shorten development cycles, improve product performance, or enhance manufacturing efficiency?

Select the Right Tools

The market offers a wide range of software. Evaluate options based on your industry needs, budget, existing infrastructure, and the required features. Consider scalability and vendor support. For example, a small workshop might benefit from more accessible, integrated CAD/CAM solutions, while a large aerospace firm might require a comprehensive PLM system with advanced CAE modules.

Invest in Training and Skill Development

Ensure your team is adequately trained. This might involve in-house training, external courses, or partnering with educational institutions. Continuous learning is key as software evolves.

Establish Robust Data Management Practices

Implement clear protocols for file naming, version control, and data storage. Consider adopting a Product Lifecycle Management (PLM) system to manage design data and workflows effectively.

Balance Simulation with Physical Testing

Use CAE to guide design iterations and reduce the number of physical prototypes, but do not eliminate physical testing entirely. Validate simulation results with real-world prototypes, especially for critical performance aspects.

Foster Collaboration

Encourage collaboration between design, engineering, and manufacturing teams. Integrated computer-aided workflows facilitate this, but a collaborative culture is equally important.

Stay Updated on Emerging Technologies

The field is constantly evolving with advancements in areas like generative design, artificial intelligence integration, and cloud-based CAD/CAM/CAE. Keeping abreast of these trends can provide a competitive edge.

Key Takeaways: The Enduring Value of Computer-Aided Systems

- Computer-aided design (CAD), manufacturing (CAM), and engineering (CAE) are integral to modern product development, enabling innovation, efficiency, and precision.

- These technologies have evolved from basic drafting tools to sophisticated integrated systems that manage the entire product lifecycle.

- CAD provides the digital environment for design, CAM translates designs into manufacturing instructions, and CAE enables performance prediction through simulation.

- Industries such as aerospace, automotive, electronics, AEC, and medical devices have been fundamentally transformed by these tools.

- Limitations include high costs, complex learning curves, data management challenges, and the inherent constraints of simulation accuracy.

- Successful adoption requires clear objectives, careful tool selection, investment in training, robust data management, and a balanced approach to simulation and physical testing.

References

- CIMdata. (Ongoing). PLM Market Reports and Analysis. CIMdata provides market research and consulting on the Product Lifecycle Management (PLM) market, which encompasses CAD/CAM/CAE. Their reports offer insights into market trends and vendor performance. CIMdata

- Sutherland, I. E. (1963). *Sketchpad: A Man-Machine Graphical Communication System*. MIT Lincoln Laboratory Technical Report No. 296. This is a seminal work detailing the foundational principles of interactive computer graphics for design. (While not a direct link to a live, easily accessible PDF, it’s a primary historical document available through academic archives.)

- Journal of Simulation Modelling Practice and Theory. (Ongoing). Academic Research on Simulation. This journal publishes peer-reviewed articles on simulation methodologies, applications, and validation, often featuring studies that quantify the benefits and limitations of CAE. (Searchable via academic databases like Scopus or Web of Science.)

- U.S. General Services Administration (GSA). (Various Publications). *BIM Mandates and Guidelines*. The GSA provides official documentation and policies regarding the mandatory use of Building Information Modeling (BIM) for federal construction projects, highlighting its strategic importance in the AEC sector. (Search for “GSA BIM mandate” on the GSA website.) GSA BIM Information

- International Journal of Manufacturing Technology and Management. (Ongoing). Research on Manufacturing Integration. This journal features studies on the practical application of manufacturing technologies, including case studies and analyses of integrated CAD/CAM/CAE workflows and their real-world outcomes. (Searchable via academic databases.)